Consistent filling, precise dosing, fewer rejects and optimised costs can all be achieved when the machinery supplier understands the characteristics of the products being handled and adapts their solution to match the producer’s needs … especially with a different technological approach.

Since the beginning of the century and, particularly in the wake of the pandemic, consumers are increasingly seeking dietary supplements.

In addition to performance-boosting nutrition for athletes, increased awareness about the benefits of preventing health issues — instead of curing them — has boosted demand for probiotics, minerals, vitamins and natural products that, for example, reinforce the immune system.

Consumers are also becoming more selective, preferring clean label ingredients with fewer excipients. In the race to satisfy the market, less conscientious suppliers have been known to implement upstream shortcuts (quality and consistency of the raw materials) that inevitably lead to processing difficulties, unwanted waste issues and avoidable downstream costs.

Whereas it is easy to obtain bulk powders, processing those with variable characteristics is not a straightforward option when the machine technology is relatively basic.

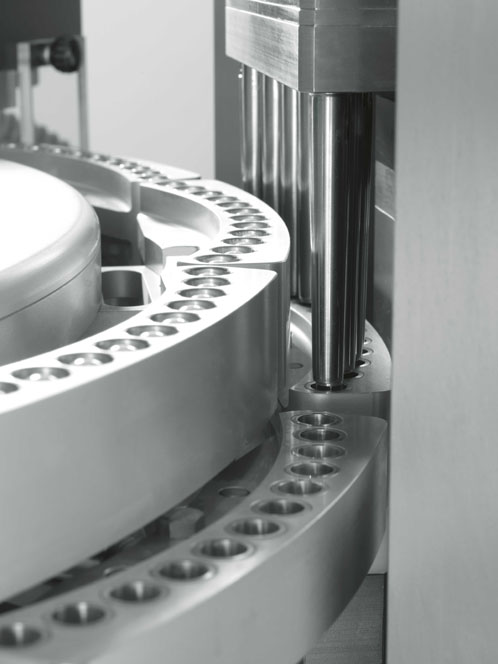

A leading manufacturer of automatic packaging solutions, IMA has nearly 60 years of experience in the pharmaceutical industry and has developed technologies to handle all sorts of powders (with and without excipients). Today, that knowledge and experience, much of which is housed in a vast database of details processing parameters, is available for the nutraceutical industry.

A closer look at the industry’s drivers

The nutraceutical industry is well aware of consumer priorities. Packing as much product into a large capsule, preferably made of natural, plant-based materials such as HPMC and modified starch, is one objective.

Packing just a few more milligrams into each capsule means a lot to many consumers; at the same time, consistent capsule weight, maximum production efficiency and minimal product waste all improve profitability for the supplier.

There are many ways to achieve these objectives, especially with a technology that’s gaining a greater share of the market thanks to a number of key benefits. This technology addresses the major issues of

- variable powder quality and characteristics

- variable capsule quality and characteristics

- stoppages and downtime between production batches.

So, what is the difference and how does it improve output and quality?

A technological solution for each issue

Powders present a wide range of characteristics, from extremely sticky behaviour to exceptional flowability; they can also possess extremely variable Carr index values. Tamping pin type capsule fillers often encounter difficulties when flowability is poor because gravity is insufficient to manage the powder correctly.

Holes in the dosing plate receive unequal quantities of powder, leading to variable slugs and capsule doses.

In most cases, the standard configuration of an intermittent capsule filler (rotating bowl and dosators) makes it possible to manage even complex powders with very different technological characteristics.

In addition, when required because of a critical product-specific issue, an exclusive feature of IMA capsule fillers (the suction bowl) increases the density of the powder by removing a significant amount of the air contained in the powder mixture.

A precompacted layer is then ready to be dosed with optimal density into each capsule. Each slug, therefore, contains a consistent quantity of the nutritional supplement throughout the batch.

When flowability is excessive, it is difficult to keep the powder inside the dosator — especially in a continuous-motion capsule filler. IMA uses an alternating motion system that, if needed, retains the powder by means of aspiration (by creating a temporary state of vacuum during transit).

The dosator then rotates and releases the slug into the capsule. This ensures that no powder is lost and each capsule is filled with the same quantity throughout the batch. Even poor flowability can present problems of machinability, and, in addition, many nutraceutical powders are formulated in 100% pure form with no excipients or binder.

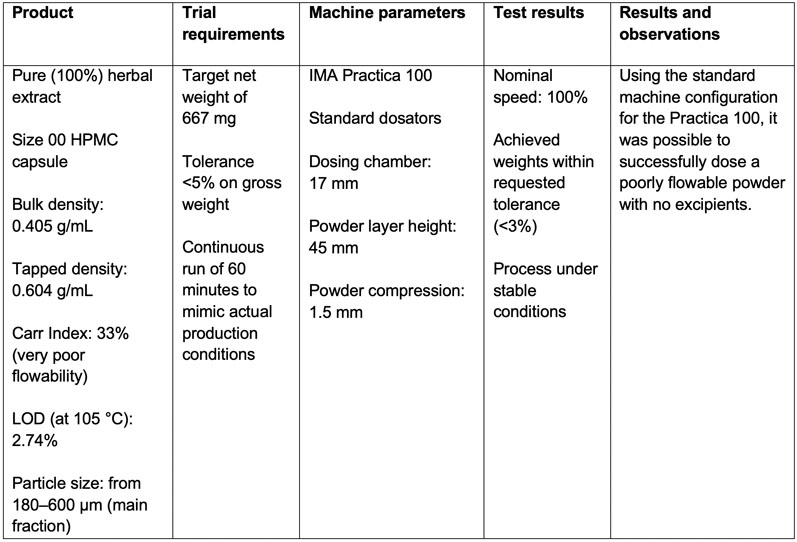

As shown below (Table I), it’s worth emphasising that, as with a standard configuration, it is possible to work at maximum speed, within the target weights and tolerances, thanks to the correct management of the powder layer height, chamber height, compression parameters and other simple optimisations.

Table I: Trial run data, machine parameters and outcomes

Maximum flexibility and high-speed processing

Producers of nutraceuticals get two major benefits with IMA capsule fillers: the ability to handle the huge diversity found in powder quality and the chance to achieve high-speed production. The technology behind IMA capsule fillers is easily adapted to suit different powder types.

Companies can simply adjust several key parameters on the machine using an intuitive HMI. When producing small batches requiring regular adjustment of the dose, the IMA capsule filler can be reconfigured in just a few minutes compared with the time required for tamping pin type equipment (30–60 minutes).

More importantly, when changing capsule format, the IMA capsule filler requires no specific alignment tool and configurations, and the parts are Poka-Yoke designed. By contrast, the tamping pin machines need alignment tools and extended assembly times (up to a full 8-hour shift).

Cleaning operations are also extremely fast with the IMA solution, so little time is lost between batches.

However, efficient performance also means high-speed production. IMA has a track record of capsule filling operations with customers in the nutraceutical industry. Each of these has generated valuable data that is now housed in a database; the acquired experience is used to benefit new customers.

The majority of the information is derived from capsule-filling lines being run at full speed … and none of the cases recorded has ever run at less than 75% of full machine speed capacity.

Greater efficiency, better quality, reduced costs

In conclusion, the technology developed and implemented successfully by IMA has proven to be effective in many ways. Producers are able to optimise the amount of powder in each capsule and can be sure of filling precision and consistency.

The diversity of raw material quality is overcome by the technological solutions or by simply adjusting the processing parameters on a batch-by-batch basis.

Rejects are rare and periods of downtime, such as during format changeovers and cleaning operations, are much shorter than alternative technologies.

In the long-term, savings are substantial. There are fewer capsules because of fewer rejects, production costs per capsule decrease because production efficiency and output increase, as does product consistency.

And, of course, the better the product is, the more the consumer will want it.