Both spray drying and fluid bed spray granulation can be used to convert liquid products into bulk materials. The most effective process will often be dictated by the desired properties of the final particles and the specific application. Glatt Ingenieurtechnik has a thorough understanding of both techniques and has a long history of designing fluid bed systems that are tailored to individual customer products.

Drying solids-laden liquids is frequently used in industry to convert products into a more manageable form and enable their storage at ambient temperatures. The resulting bulk materials are not only more stable than the original liquids, they also have lower weights and smaller volumes, significantly reducing transportation and storage costs as well as any handling issues.

To dry liquids as quickly as possible, spraying them into a hot air stream (spray drying) is very effective. It has been used for decades to quickly and cost-efficiently dry large-volume bulk products such as milk powder. In addition to being suitable for large volumes, spray drying is also well suited for products with a low solids content as quite high temperatures can be used.

Owing to the fact that a lot of water is evaporated, the cooling effect and the short residence times, any heat-induced damage is minimised. Nevertheless, the fine particles generated can create dust problems, especially when enzymes or other proteins are involved. They are, however, often potent allergens and, finely distributed as dust, are highly effective even in low concentrations and require further processing.

Targeted adjustment of product properties

Fluidised bed spray granulation processes take the basic idea of spray drying to a completely different technological level and offer targeted solutions for a wide range of material systems, applications and industrial sectors. The general advantage is as follows: compared with spray drying, the product properties in the fluidised bed process can be adjusted in a very targeted manner.

Depending on the choice of process parameters and the technical configuration of the plant, particle shape, structure and size can be defined and produced almost without limits.

This is made possible by combining two process steps: convective drying or solidification and particle formation. Particle sizes from 200 µm to 2 mm can be achieved with ease.

By contrast, spray drying only produces particles of about 10–300 µm in diameter. The dispersed droplet dries as it falls down the spray tower and, as such, droplet size is limited by tower height. Significant particle growth requires an additional agglomeration step.

The principle of fluidised bed spray granulation

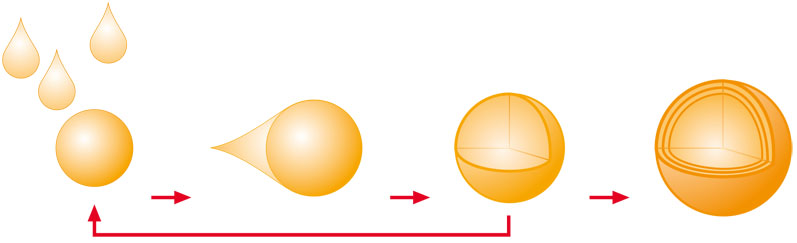

In contrast to spray drying, during which the liquid containing solids is atomised in an empty process chamber, in spray granulation it is sprayed into a bed of fluidised particles. The solvent — usually water or an organic solvent — quickly evaporates so that particle growth occurs by droplet formation and film drying (Figure1).

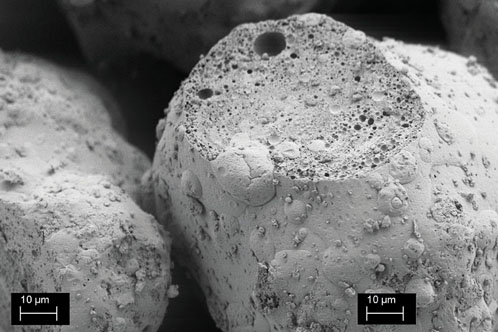

Figure 1: Structure principle of spray granulated particles with an onion-like structure

Parallel to this process, which is also called granulation drying or build-up granulation, new nuclei are constantly generated.

They can be done in two ways: in the process itself, they are formed by abrasion and/or the fact that some atomised droplets miss the particles suspended in the fluidised bed and dry directly (as in spray drying). Externally, granulation nuclei can be formed from fine particles or crushed granulates derived from the grinding-screen circuit.

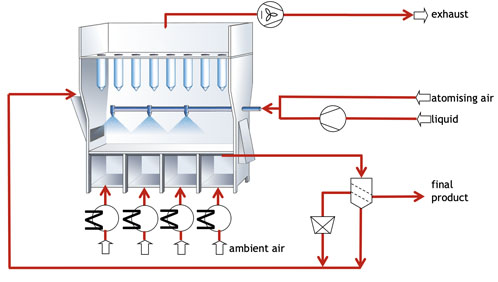

In the grinding-screen circuit, oversize and undersize particles are separated, usually crushed by a pin mill and fed back into the process. Both the direct (spray drying) nucleation — the so-called overspray — and the indirect nucleation control the steady growth of the particles during the process and form the basis for stable and continuous granulation (Figure 2).

Pushing the limits of spray drying

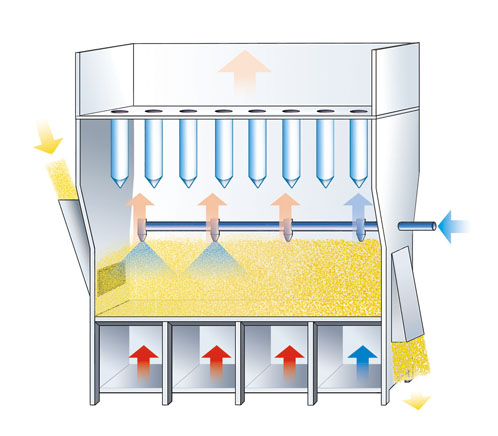

Continuously operated fluidised bed spray granulation systems — because of their multichamber design (Figure 3) — offer the possibility to combine several process steps. Theoretically, a rectangular fluid bed system can be built to any length, so that different product properties can be set in the successive process chambers to produce custom particles.

Figure 2: Principle of a continuous fluid bed process with a grinding-screen circuit

In a customer project, for example, Glatt process engineers succeeded in generating readily soluble powdery particles from a solution of hydrolysed proteins by using a fluid bed with an initial spray-drying step. In the course of the process, these were then compacted and agglomerated in subsequent unit operations until particles with a higher density were produced.

These particles dissolved faster in water as they sank below the surface more quickly than purely spray dried products. Similar spray granulation processes can also be used to dry products by combining solubility with a higher bulk density for smaller packaging units (Figure 4).

Figure 3: Fluidised bed spray granulation processes offer targeted solutions for a wide range of material systems, applications and industrial sectors

Customised system design and process parameters

Multichamber fluidised bed systems can spray from above or below; furthermore, intermediate drying and cooling steps are possible and/or subsequent cooling can be done in the same unit. In addition, fluidised bed spray granulation systems to handle organic solvents or oxidation-sensitive products can easily be integrated into a closed-circuit environment.

An essential difference between spray drying and fluidised bed spray granulation lies in the particle size and morphology: in spray drying, the individual particles dry from the outside inwards; in fluidised-bed spray granulation, the structure is layered and the particles dry in the opposite direction from the inside outwards.

The hot air stream in which the spray droplets dry generates a hard outer shell — increasing the concentration of the dissolved component — while the inner core of the particle is still liquid.

As the temperature increases, this moisture evaporates and diffuses, causing hollow spheres. Indentations in the particles occur if the moisture escapes abruptly; depending on the drying speed and the solids concentration of the liquid, the particles might rupture.

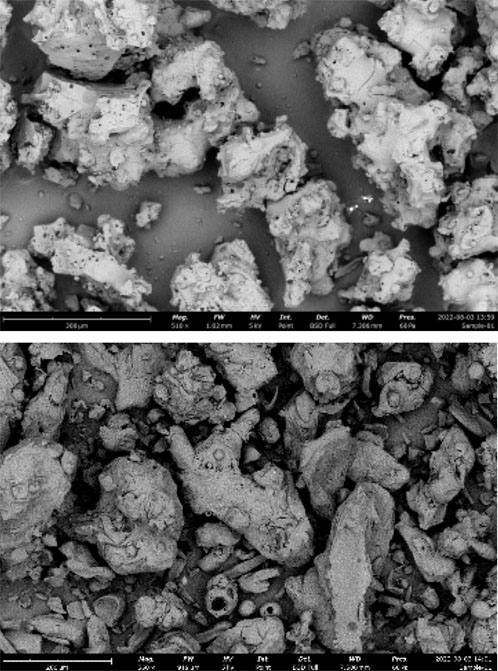

In certain fields of application, such as the microencapsulation of active ingredients, these particle properties are unsuitable as the aim of microencapsulation is to protect the encapsulated actives from ambient conditions. The aim is to have as little surface area as possible (Figure 5).

Figure 4: A fluidised bed spray granulation product (above) compared with the same product made in a classic spray tower (below)

Advantages of spray granulation

Spray granulation produces solid, compact and round spheres with an onion-shaped structure by building up the product layer by layer. Build-up granulation — the so-called layering effect — enables flexible and complex product design as particles can be formed from different solid layers and cores can be loaded and coated (Figure 6).

This offers nutraceutical manufacturers the ability to functionalise their products in a targeted manner and equip them with greater added value. In addition, coating the previously spray granulated particles can be done in the same apparatus, for example, to achieve a retarding effect, to protect the active component from external influences or to mask an unpleasant taste or odour.

Spray granulates differ from dried products in that the particle properties, such as size, shape and structure, can be adjusted depending on the application. Fluid bed spray granulation is highly recommended for sensitive nutraceuticals, for example, and for converting emulsions and oils into very compact particles.

Figure 5: REM picture of a cut granule with microencapsulated oil

Owing to the smaller surface area compared with spray dried products, these nutraceuticals are better protected against oxidation than in a powder agglomerate. In addition, the drying temperatures are lower compared with spray drying.

Trials in the laboratory and on pilot-scale plant are the most important step in process and product development for fluidised bed spray granulation. Glatt Ingenieurtechnik from Weimar, Germany, therefore monitors every fluid bed project, very closely, right up to installation, commissioning and process acceptance at the customer’s site.

Figure 6: The onion-shaped structure in amino acid granules

Beyond the development of customised and functionalised products or tailor-made processes, Glatt offers a wide range of services from project initiation, development and delivery to supplying turnkey factories.