As the planet’s population continues to grow and the climate unravels at pace, a new food transition seems more than necessary to save Earth and everything that lives on it.

Almost one in two consumers worldwide have already changed their diet in recent years to adopt a more sustainable lifestyle. In response to this, companies in the food and beverage sector are finding novel ways to innovate in a more environmentally friendly way.

From upcycled and/or organic ingredients to carbon neutral and local products … or manufacturing processes that save water and/or energy, plant-based foods offer several ecofriendly benefits compared with animal-based ones.

Some of the often-discussed advantages include, at the top of the list, climate change mitigation and reduced greenhouse gas (GHG) emissions. Animal agriculture, particularly beef and dairy production, is a significant contributor to GHGs.

Plant-based foods generally have a lower carbon footprint; growing crops for food requires fewer resources and emits fewer GHGs compared with raising animals for meat and dairy. Reducing demand for animal products downscales a significant contributor to atmospheric pollution.

At the same time, animal agriculture is both land- and water-intensive. Producing plant-based foods typically requires less water than raising animals. For example, it takes significantly more water to produce a kilo of beef compared with a kilo of grains or vegetables.

Similarly, animal husbandry requires vast amounts of land for grazing and to cultivate feed crops. Plant-based diets generally use land more efficiently because plants yield more food per acre compared with raising livestock.

Choosing plant-based foods also decreases deforestation and land degradation. Animal agriculture often involves clearing forests or natural habitats to create space for livestock or their feed crops. Choosing plant-based options reduces the demand for land conversion, thereby helping to preserve biodiversity and ecosystems.

The protein perspective

Very much aligned with these key themes, Allyson Fish, President, Global Plant and Alternative Proteins, provided an ADM viewpoint. “The global food industry is experiencing a massive shift and focusing on addressing three macro trends: sustainability, food security and health/well-being, each of which are impacting the technologies, solutions and products that are essential to meeting the needs of people and the planet — both now and for generations to come.”

She added: “Expanded protein choices, whether they are from plants, animals or novel sources, are crucial to feeding the growing global population while keeping what’s best for the planet in mind.”

“By expanding our protein portfolio, advancing our capabilities, collaborating with food technology companies and working with local farmers, we’re supporting a more secure and sustainable future."

"We help farmers to implement regenerative agriculture practices that mitigate GHG emissions, increase soil carbon sequestration, improve water quality, promote biodiversity and enhance overall soil health. Additionally, we have committed to achieving 100% deforestation-free supply chains by 2025,” she added.

The company’s new and expanded facilities in Serbia, Germany and the US, for example, support localised protein solutions and research-focused innovation. “Local sourcing and regional capabilities are crucial to creating an integrated value chain and bringing more preferred protein options to consumers,” she states.

In conclusion, Allyson comments: “Variety is influencing the future of protein and is driven by a mix of sources and hybrid offerings, particularly as new technologies such as precision fermentation represent what’s next in this space.

ADM is accelerating the possibilities of protein production, leveraging an extensive library of plant-based solutions, systems, novel technologies and key investments and partnerships.”

From farm to fork

Producing plant-based foods generally requires less energy compared with raising animals for food. The energy inputs to grow crops are often lower than those for animal agriculture, which involves feeding, housing and transporting animals.

Nathalie Sadin, Corporate Sustainability Manager at BENEO, takes up the charge and notes: “With this in mind, BENEO offers a versatile range of plant-based ingredients to help producers deliver products with improved nutritional profiles and sustainability credentials. It’s thought that, globally, almost three out of five consumers are now interested in plant-based nutrition and meat hybrids."

“To make our offering as sustainable as possible, we focus on the entire value chain; this includes support that focuses on long-term partnerships with farmers, production level investment in efficient processes and renewable energy sources, as well as full valorisation of our raw materials,” she says.

“Our faba bean ingredients, which are used in a wide range of plant-based recipe formulations, are a great example of this focus. At farm level, faba beans don’t require nitrogen fertilisers and actually improve the soil quality for subsequent crops."

"BENEO’s pulse-processing plant near the faba bean fields in Germany, which is currently under construction, will be supplied exclusively by green electricity,” she adds.

Thanks to the company’s sustainability focused production level investment, part of this power will be generated by a photovoltaic system on the roof, whereas waste heat from the production process will warm the building.

“Additionally, water is not needed when processing the pulses and we use the entire faba bean to create ingredients for the food and animal feed industries, ensuring no waste is produced,” says Nathalie.

When it comes to supporting the transition to a more environmentally beneficial plant-based diet, BENEO’s core expertise in terms of connecting nutrition and health, in combination with application technology, is also a crucial asset.

“After all,” she observes, “consumers will only continue to demand more sustainable meat, dairy and bakery alternatives if they are satisfied with the nutritional profile, taste and texture of the end products.”

Taste is everything … still!

Maud Joassard, Marketing Manager, Naturals, at Syensqo (formerly part of the Solvay Group), couldn’t agree more. “The nutrition segment is rapidly growing as new health-conscious, protein-seeking consumers join the market."

"With consumers requesting high-protein content foodstuffs and more plant-based alternative proteins, the challenge of effectively masking the inherent off-notes and bitterness of such proteins remains.”

“Today’s consumers expect more than just health benefits from their products,” she explains: “Demand is also shifting towards products based on natural flavours with enhanced taste profiles and sustainability benefits, such as the use of upcycled and/or circular ingredients.”

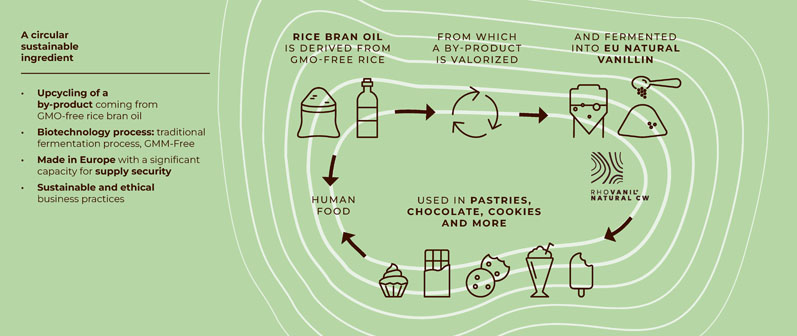

Mainly known for its flavouring capacity, Maud believes that natural vanillin is the solution of choice to tackle these challenges (Figure 1).

“Rhovanil Natural is natural vanillin derived from a rice bran oil by-product. The by-product is valorised and fermented into EU natural vanillin, thereby upcycling the by-product as it is reintroduced into the food value chain."

"The circular production process does not use GMO raw materials; plus, it’s natural and free from genetically modified micro-organisms (GMM). These latter points are also important when we define sustainable production.”

Figure 1: Rhovanil Natural is a circular and sustainable ingredient.

“Syensqo’s natural vanillin can therefore play a multifaceted role in plant-based foods,” Maud continues, “not only as a flavour enhancer but also to address specific taste challenges. For instance, natural vanillin’s ability to inhibit bitter molecules, such as peptides and amino acids, makes it valuable in terms of neutralising undesirable flavours.”

She concludes: “By using Rhovanil Natural vanillin, plant-based food producers can address several key requirements to ensure consumer satisfaction: taste, nutrition and demand for sustainable products (based on circular/natural ingredients and processes).”

Lowering carbon dioxide emissions

Animal agriculture contributes to various forms of environmental contamination, including water and air pollution from manure, antibiotics and the chemicals used in feed. It’s something that David Faguer, Global Plant-Based Lipid Director for Bunge, was keen to talk about.

“Since the early 2000s, we’ve witnessed the gradual shift to conscious consumerism across the globe wherein individuals make food purchasing decisions based on their contribution to overall well-being as well as environmental and social responsibility values. This has driven many consumers to adopt plant-based or flexitarian eating patterns.”

“As food formulators and innovators in the field of plant-based lipid solutions, we are continuously keeping our finger on the pulse of these trends to create plant-based fat solutions that not only align with consumers’ ethical concerns … but can also deliver on the sensory appeal of real dairy fats.”

He explains: “Beleaf PlantBetter is a groundbreaking plant-based butter replacement that’s uniquely crafted to match standard dairy butter in terms of taste, texture and functionality."

"It gives a butter-like sensation to a wide array of applications — from spreads to bakery, confectionary and dairy products. Our approach was systematic, involving the rigorous testing of more than 150 product concepts, each meticulously compared with the industry’s gold standard — dairy butter — to reach the desired result.”

Primarily composed of a blend of coconut, cocoa butter, rapeseed and lecithins, all from natural sources, Beleaf PlantBetter offers a conscientious choice for both manufacturers and consumers. It’s a plant-based, non-GMO and label friendly ingredient that has not been hydrogenated; it’s also palm-, lactose- and soy-free.

“Beleaf PlantBetter is also 50% less carbon-intensive compared with traditional dairy butter,” notes Anabel, “owing to the sourcing of its core ingredients. Specifically, Beleaf PlantBetter boasts a product carbon footprint (PCF) of approximately 5.9 kg of carbon dioxide emissions. This substantial reduction has been independently verified in a third-party study conducted by the Terra Institute.”

Beyond the product

Adding the last word, Diana Visser, Vice President of Sustainability at Corbion, notes: “In the ever-evolving landscape of sustainability, Corbion emerges as a pioneer by placing preservation at the forefront of its mission. With a commitment to preserving what matters — from food and production to overall planetary health — the company is making significant strides in terms of redefining industry standards.”

An example of Corbion's dedication to sustainability is the implementation of its innovative Circular Lactic Acid (LA) technology at its new plant in Rayong. This technology sets a new paradigm by recycling almost all chemicals, optimising resource efficiency and eliminating by-products.

“Corbion’s commitment to preservation extends beyond the end product, adds Diana: “It’s ingrained in the very fabric of our processes. By adopting environmentally conscious practices, the company not only minimises its carbon footprint but actively contributes to a more sustainable future.”

Corbion stands firm in prioritising ecological responsibility, ensuring that every step of its production journey aligns with a commitment to a more sustainable future.

“As the spotlight on corporate responsibility intensifies, Corbion's sustainability initiatives stand out as a beacon of responsible business practices. In an era when consumers demand more than just products, Corbion's innovative processes and products offer a compelling narrative — one where environmental stewardship and business success harmoniously coexist.”