The wide ranging and challenging events of the last few years saw many companies employing the extensive services of contract development and manufacturing organisations (CDMOs) and copackers to ensure the continuity of their business.

Several of these hurdles remain, such as inflationary pressure, material price rises/supply, labour shortages or the massively increased cost of supply to European clients from the UK (because of Brexit). And yet, third-party outsourcing continues to overcome them.

Consistent supply

With material sourcing still uncertain, it’s often the case that, when found, CDMOs and copackers will seek to order additional stock to ensure continuity of supply to their clients. The provision of additional warehousing is essential to accommodate this higher level of stockholding.

Meeting new needs

The health product and nutraceuticals sector has remained strong and continues to grow in popularity — in no small part fuelled by an increased awareness of the importance of diet and well-being that was heightened by the pandemic.

Supplements and vitamins remain in high demand, with a specific focus on vitamin D, nootropics and liposomal vitamin products. Meanwhile, the retail environment is now irretrievably focused on direct to customer (D2C) delivery, e-commerce and fulfilment channels.

New technology

An increased desire for personalisation within this D2C environment has further created demand from clients for bespoke and highly agile responses from their third-party outsourcing partners.

Virtual platforms (allowing access to real-time stock levels and production schedules) and the extended use of AI, developed by fulfilment partners, are becoming increasingly prevalent in serving the D2C sector and are invaluable to brands, retailers and manufacturers alike.

Jenny Dixon, Business Development Director at Chester Medical Solutions, adds: “Outsourcing to a knowledgeable CDMO or copacking partner can provide access to this growing sector for both start-up and larger companies, ensuring a quick turnaround and an agile response for consumer convenience.”

Enhanced support

These blossoming new opportunities in D2C and packaging solutions have seen continued growth. From sourcing new, alternative ingredients and packaging materials — as supplies remain scarce — to meeting the demands of a growing sector, clients are relying heavily on the expertise of third-party outsourcing partners to find fast, effective and alternative solutions to getting their products to market.

Further strengthening these relationships, many organisations are starting to see the benefit of outsourcing the entire production and delivery process — from ingredient procurement, manufacture and packaging to final customer despatch — to a single third-party supplier.

Investing in strong foundations for further growth

To meet the expanding demands of their customers for the flexibility, creativity and in-depth knowledge of third-party outsourcing firms, BCMPA members are investing heavily in new capabilities, technologies, automation and facilities.

Clare Campbell, Managing Director of Health Innovations, shares a prime example of this forward-thinking and positive commitment to maintaining the momentum for growth in nutraceuticals.

“We have invested more than £1 million in our manufacturing and packing site in Skipton, North Yorkshire, to support our ongoing commitment to product innovation within the food supplement sector. We recognise that investing in innovation will lead to long-term commercial stability and benefits in efficiency, productivity, competitiveness and, ultimately, business growth.”

Extending capabilities

In conjunction with this enhancement in manufacturing and warehousing capacity, BCMPA members are also making significant progress in terms of broadening their capabilities in a range of services to ensure that more client requirements can be satisfied.

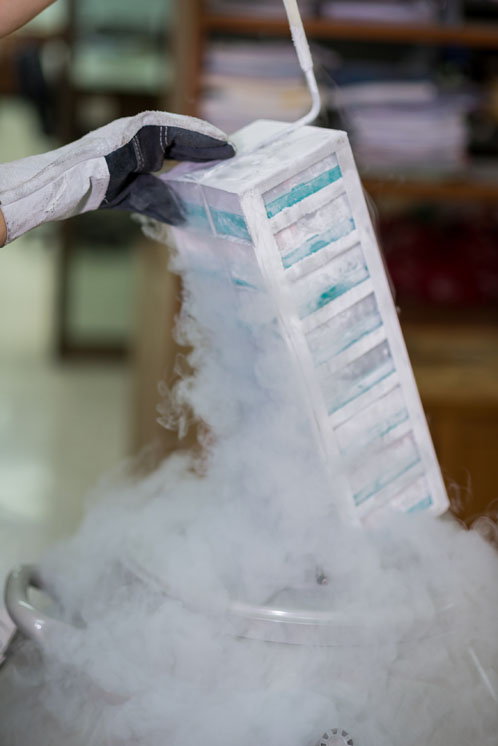

Examples of this are varied and extensive, including the provision of storage facilities down to –20 °C and the introduction of liquid nitrogen storage, thus widening the range of products that can be stored and distributed.

CDMOs and copackers are adding further production services throughout their operations, including new and more efficient film coating lines (as seen at Health Innovations, which now has one of Europe’s largest machines).

Additionally, new filling systems and more adaptable packaging machinery are allowing CDMOs and copackers to broaden the scope of their offering to meet new customer requirements.

As a result, BCMPA members are continuing to extend other operational capabilities. For instance, Chester Medical Solutions is investing in additional services and adapting its offering to further support its clients, including a new CAD/CAM system for quick turnaround carton sampling and prototyping in Deeside.

As Dixon notes: “We are the only nutraceutical contract packer in the UK that also manufactures cartons and leaflets in house, offering a complete service to our customers.”

Ian Robinson, Group Business Development Director at Central Pharma, supports this drive: “As our business, and the vitamins, minerals and supplements (VMS) market in particular, maintains its significant growth, we are continuing to extend both our production capacity and our capabilities in this and other areas, including the further incorporation of AI inspection systems and advanced planning modules, all while increasing staffing levels to meet growing demand.”

Growth in the extended provision of production, packaging and technical capabilities from CDMOs and copackers is a strong indication that their services are increasingly being regarded as a “one stop shop” solution for many brands, retailers and manufacturers.

The range of support offered now allows many of them to delegate further production, planning and distribution tasks to third-party suppliers.

Sustainability

Production advances are also providing for the development of more environmentally sensitive packaging options, reducing the existing dependence on plastics and meeting the continued and industry wide demand for more sustainably produced packaging.

A particular focus is the production of ecofriendly sachets and pouches, minimising the amount of material used within packs and increasing the proportion of recycled/recyclable materials from which they are constructed.

Central Pharma’s new in-house recycling plant provides for the conversion of all blister packs into a recyclable form that can be reused beyond pharma applications. This already aligns them with WRAP’s 2025 Plastics Pact targets.

Robinson comments: “Blister packs are a composite of PVC and aluminium, making them difficult to recycle, so our new facility is preventing millions of blister packs ending up in landfill each year.”

Dixon has seen particularly high interest from clients in this field: “The demand for sustainable products and packaging continues to grow and we have responded accordingly; from environmentally friendly blisters to recyclable and compostable sachets, pouches and pots that can be easily recycled or have a larger percentage of recycled material as part of their composition, brands want to demonstrate true sustainability. Our Deeside site, which manufactures cartons and leaflets, is FSC accredited and ISO14001 approved.”

Research and development

Going beyond the mere functional solutions to the ever-changing requirements of retailers, brands and manufacturers, CDMOs and copackers in the pharmaceutical and nutraceutical sector are providing further resources in the research and development (R&D) of products themselves, creating in-house R&D teams to explore new possibilities.

As well as sustainability, increased convenience is also at the forefront of planning for brands, retailers and manufacturers. From a daypack with a chosen vitamin combination to take on-the-go or individual sachets of an organic superfood blend, which can be mixed into snacks of choice, CDMOs and copackers, such as Chester Medical Solutions, are constantly developing new products and deliveries.

Dixon notes: “People are embracing being back to work after lockdowns and restricted office access, but see huge advantages in being able to maintain their personal health and well-being conveniently."

"They want their daily health boost in handy doses and in easy to consume forms. We are supporting this double-win demand for both convenience and sustainability.”

Campbell adds: “Our new development laboratory is equipped with pilot equipment so that we can enjoy interactive and practical development days with our customers prior to scaling-up in the factory. We are looking forward to seeing some truly innovative products developed here that hit the shelves in the near future.”

Pragmatic collaboration

This closer collaboration, given the now firmly established third-party outsourcing relationships that exist, demonstrates that regular contact, reporting and liaison between client and CDMOs and copackers has never been more vital.

Dixon confirms this: “We need to be closer than ever to those who feed into our business and also those who complete the fulfilment loop to the end user.

As we continue to think creatively and solve challenges, that trust and relationship can only come from working hand in hand with both our customers and suppliers to maintain a robust supply chain in today’s challenging landscape.”

Many BCMPA members are witnessing similarly rewardingly responses from customers in terms of understanding the continued testing conditions that remain in the field of supply chain fragility and raw material availability.

It is vital that both sides of the partnership engage as fully as possible in the areas of forward planning, stockholding and product development to ensure these challenges are met effectively.

Although supply issues are certainly improving, prices and lead times are still far greater than before the pandemic. Some material lead times remain in excess of 10 months, which places tremendous strain on certain supply chains and planning functions.

Robinson notes: “Thankfully, our relationships with clients have become even closer, particularly regarding the forward planning process. This closeness has enabled us to navigate the choppy waters created by poor material availability within global supply chains.”

The future

There seems little doubt that the strong bond between brands, retailers and manufacturers, and the highly innovative and resourceful CDMOs and contract packers in the nutraceutical sector, will remain a potent driving force.

Indeed, as consumer demand continues to change and grow, and innovation in the supply of both cost-effective and more sustainable packaging solutions accelerates, the role of third-party outsourcing may well change from being merely a supporting resource to a leading platform in framing the future of nutraceuticals.