Most people’s diets don’t contain enough omega-3; but, thanks to years of media hype and widely available information, they are well aware of this! Food supplements, fortified drinks and dairy products and/or vegetable oils have therefore become very popular.

Regardless of the application and no matter whether the raw material from which the oil is to be extracted is a vegetable or animal product — such as fish, linseed, chia, rape or microalgae, for example — it should be refined to remove possible contaminants and unwanted taste, smell or colour.

The challenge is that crude oils with a high content of polyunsaturated fatty acids such as omega-3 are unstable and susceptible to oxidation.

“Omega-3 oils require a completely different handling process and a higher degree of care than ordinary oils. Preserving these valuable fatty acids and ensuring that the product remains stable and free from contaminants can be quite challenging,” explains Frank Möllering, Head of R&D at the Swiss refinery, Nutriswiss, which specialises in purifying, modifying and refining edible and specialty oils for national and global markets.

Growing awareness and need

According to a recent study, the global market for marine and plant-based omega-3 products was valued at approximately $2.49 billion in 2019 and is expected to grow to more than $4 billion by 2027.1 It comprises dietary supplements, functional foods and beverages, pharmaceuticals, infant formulas, pet foods and feed.

In addition to the increased awareness of the importance of unsaturated fatty acids for health, the growing world population is also playing a role — as is the fact that, in many countries, it’s now a legal obligation to formulate omega-3s into baby foods (and the required concentrations have increased).

Fish are still the dominant source, but alternatives are becoming more popular and gaining market share. The main reasons for this are, on the one hand, the fishy aftertaste, which is often associated with capsule-based products and, on the other hand, increasing consumer demand for non-animal offerings.

A Canadian study by Dalhousie University concluded that 96% of the world’s population will be susceptible to a DHA (docosahexaenoic acid) deficiency by the year 2100 owing to climate change and overfishing of the oceans. The reason being that the amount of available DHA from wild, farmed and freshwater fish will decrease by around 58% as climate change and ocean warming continues.2

Essential for cells

For a long time, the consumption of fatty fish such as salmon, herring and other marine animals such as mussels and Antarctic krill were considered to be the only sources of DHA (docosahexaenoic acid) and its precursor EPA (eicosapentaenoic acid). These omega-3 fatty acids are essential for heart health and brain function.

They are also considered to be particularly important for the healthy development of newborns and children. The World Health Organization (WHO) recommends 1–2 servings of fish per week or an equivalent substitute that delivers 200–500 mg of EPA and DHA.3

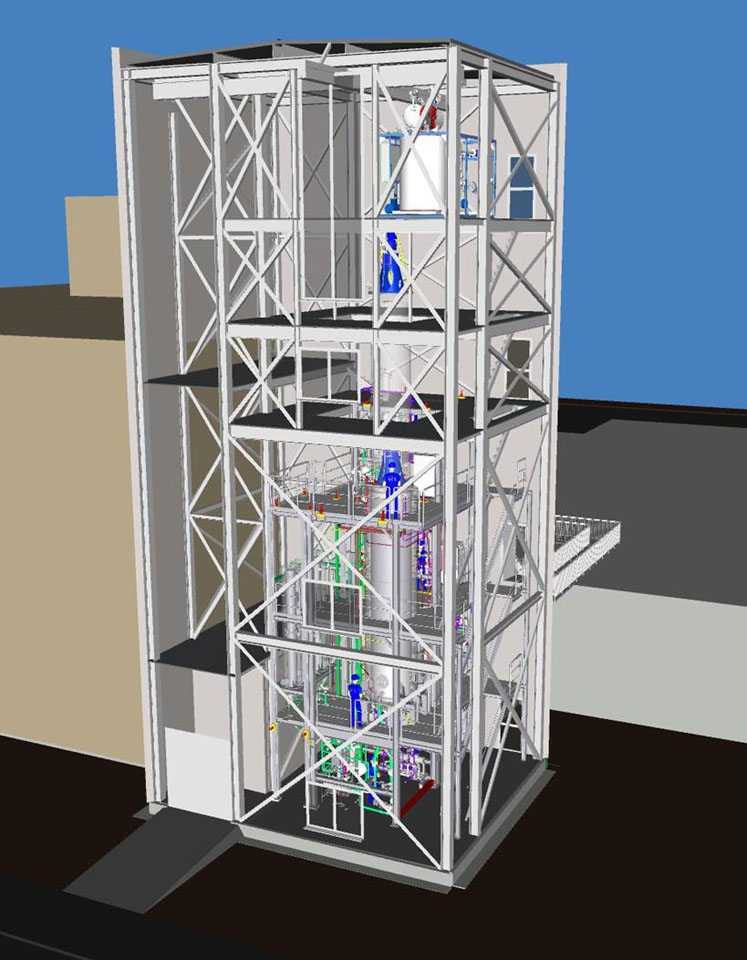

Figure 1: Short path distillation uses a high-power vacuum to remove contaminants in a particularly gentle way, which helps to preserve essential fatty acids

In recent years, however, vegetable sources such as nuts, seeds and oils (such as rapeseed) have also become increasingly popular; chia and linseed are currently being used as popular toppings in healthy bowls or shakes, for example. They mainly contain the omega-3 fatty acid, ALA (alpha-linolenic acid), which, however, must be converted by human metabolism to DHA and EPA … and is only partially and often inefficiently done.

As true all-rounders, inconspicuous microalgae have, for some time, been the focus of attention in various branches of industry; they can be cultivated and reproduce quickly, which is why they are considered to be a sustainable marine source of omega-3.

Another trump card is that algae are the only plants that contain both DHA and EPA. “Fish get their omega-3 from algae — so why not start directly at the source?” says Möllering: “In addition, algae cultures are more environmentally friendly and protect fish stocks."

"The market is still in the discovery phase but, because we’ve been involved in the purification of algae oil for several years now, our expertise in this field is in great demand. We now process almost as much algae oil as fish oil.”

Quality counts

Regardless of the source, a high proportion of polyunsaturated fatty acids, as mentioned above, makes the oil unstable and susceptible to oxidation. Unlike vegetable oils, the oxidation reaction causes fish oil to develop a strong odour, darken in colour and rapidly become rancid.

For sources with extremely high omega-3 contents, such as tuna oil, which contains 25% DHA, the oxidation potential is correspondingly high. To prevent these quality defects, both the raw material and the refined oil must be kept in a protective atmosphere until they are processed into the end product. This is the only way to prevent contact with the decomposing oxygen.

At Nutriswiss, a comprehensive “key figure” profile is initially compiled in the factory’s own analytical laboratory for each received oil to determine how much “damage” has already occurred. Key factors such as the anisidine value, which measures the secondary degradation products of lipid-compound oxidation — such as aldehydes — provide information about the history of the raw material.

“Using various process steps, we can remove the secondary oxidation products and reduce the anisidine value below 10. For a fish oil, this is premium quality! The refined oil is also absolutely neutral from a sensory point of view and is almost the same light-yellow colour as rapeseed oil,” Möllering emphasises.

According to the Head of R&D, vegetable oils also have a high oxidation potential, with more than 50% unsaturated omega-3 fatty acids being present. But, “compared with highly sensitive fish oils, refining a linseed oil, for example, is child’s play,” he adds.

After the refining process in Switzerland, the excellent quality attributes of these vegetable oils are such that they’re in high demand in a wide range of sectors, including food, infant formula and pharmaceuticals.

Contaminants

Oxidation products are not the only compounds that have to be removed from a crude oil by refining, however. Owing to their apolar structure, lipids are especially susceptible to environmental contaminants. Oils from plants often accumulate the insecticides, fungicides and herbicides used in traditional cultivation.

In addition, mineral oil saturated hydrocarbons (MOSH) and mineral oil aromatic hydrocarbons (MOAH) may have been transferred to the foodstuff during processing and packaging, originating from exhaust gases or emissions from industrial plants, among other sources.

Marine animals are particularly at risk: even pesticides that have been banned worldwide for decades, such as polychlorinated biphenyls (PCBs), are still present in waters around the globe and accumulate in the fatty tissue of organisms.

Figure 2: After the last refining step, the oil is filled into different containers according to customer requirements

Another example is dichlorodiphenyl trichloroethane (DDT), which has been prohibited in most industrial countries since the 1970s, but its application as an anti-malarial continues to this day and the insecticide still finds its way into our oceans and the food chain.

For manufacturers who, owing to their market positioning, require uncontaminated oils of the highest quality and purity for their formulations, Nutriswiss also offers access to a self-developed supply chain. As is already the case with oil plants derived from certified contract cultivation, the Swiss also work with selected partners for marine sources who have committed themselves to the highest standards in terms of catch methods, breeding and transport.

Gentle contaminant removal

As with almost all sensitive natural raw materials, the challenge is implementing a gentle purification process to preserve the valuable polyunsaturated fatty acids. To remove the contaminants, high temperatures are required, which in turn favours the formation of other contaminants (trans fatty acids and chlorine-fatty acid esters such as 3-MCPD, for example).

For 3-MCPD, in particular, more stringent regulations are due to come into effect in the EU for infant foods in January 2021. And, tighter restrictions are also being considered for other residues and applications.

Nutriswiss is already prepared for more rigorous legislation and now offers customers a new process technology based on short path distillation (SPD). It’s a particularly gentle thermal separation process and has already been established in the fish oil sector.

Further developed and implemented as one of several purification steps, the plant concept allows contaminants to be removed without generating new ones (Figure 1). The finely controlled vacuum in the new plant prevents the formation of process contaminants such as 3-MCPD or glycidyl fatty acid esters and, at the same time, completely removes ortho-phthalates plasticisers and many pesticides.

Other pollutants, including MOSH/MOAH can also be reduced significantly.

The gentle process protects micronutrients and can be used to maximise the yield of omega-3 fatty acids.

Subsequently, the sensory quality can be further optimised by adding various absorbents — such as activated carbon — and during the deodorisation stage (Figure 2). The final refining steps are only done directly before delivery to keep the storage times short and to prevent oxidation as far as possible.

Tailor-made solutions

Developing custom products is one of the great strengths of the small Swiss refinery. Before production starts, each process and method is tested in the laboratory, so that all procedures and methods can be adapted to suit individual applications. Afterwards, scale-up — from small quantities of around 500 kg batches of several tons — can be done, which can be particularly interesting when developing novel foods and other specialities.

Nutriswiss also offers advice on sourcing and helps with the selection of the highest quality raw material sources. The company’s portfolio currently includes more than 20 different types of oil and continues to grow.

In addition to omega-3, the Swiss organisation also refines gamma linolenic acid from evening primrose (Oenothera biennis) or borage (Borago officinalis), an omega-6 fatty acid with corresponding nutritional benefits for certain consumer groups. Even insect oil has been purified on a laboratory scale.

Frank Möllering concludes: “It’s always exciting when a customer approaches us with a new application idea or a novel raw material. When we started refining fish oil, it took many trials until we got both the key figures and the sensory system right. But, we persevered until we perfected the process. In fact, as small-scale experiment with very discerning customers, I baked a Gugelhupf (yeast based) cake with fish oil for my children … and they didn’t notice any difference.”

References

- Grand View Research, “Omega-3 Market Size, Share and Trends Analysis Report By Type (EPA, DHA, ALA), By Source (Marine Source, Plant Source), By Application, By Region, And Segment Forecasts, 2020 – 2027,” (2020).

- S. Colombo and T. Rodgers, “Projected Declines in Global DHA Availability for Human Consumption as a Result of Global Warming,” Ambio 49, 865–880 (2020).

- www.who.int/nutrition/topics/5_population_nutrient/en/index13.html.