Daily Manufacturing is a small, family orientated business committed to producing high quality nutritional products from natural sources such as vitamins and minerals, digestive aids ranging from activated charcoal to probiotics, herbs and special combinations of these ingredients. Founded in 1979 by James and Mary Jo Daily, the company originally manufactured only one product for Dr Carey Reams, an agricultural biochemist who eventually developed an entire line of high quality nutritional products derived from natural sources.

From this humble beginning, Daily Manufacturing has grown to become the manufacturer of all the products sold under both the Reams brand name and its own, as well as a leading supplier of natural ingredients to nutritional product manufacturers throughout the world. A key step in the manufacturing process is blending the various ingredients that make up each of the company’s more than 50 different products. Compliance with US Food and Drug Administration (FDA) sanitation standards is critical, as the agency performs regular inspections of the company’s manufacturing facilities.

“The 0.425 m3 ribbon blender that we formerly used was difficult to clean, especially the centre shaft, which was difficult to reach,” explains Jim Daily III, Vice President and son of the founder. “It also had internal bearings that became damaged by the abrasive particles that we process and had to be replaced frequently because fine powders could escape.

Ease of cleaning between batches was an important consideration

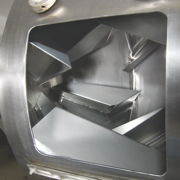

“We replaced it with a Munson Mini Rotary Batch Mixer in which the drum rotates on external twin pillow block roller bearing assemblies rather than having an internal shaft and bearings. It gently but thoroughly mixes ingredients with different bulk densities, generating much smaller amounts of fine powder than the ribbon blender. It is also easy to clean when we switch products,” he says.

Products Derived from Natural Sources

“We prefer to use the most natural ingredients available,” says Dr Daily, a PhD chemist. “Natural and synthetic vitamin C, for example, are chemically identical, but foods rich in vitamin C are also rich in many phytochemicals such as bioflavonoids that act as antioxidants. Many of our preparations incorporate small quantities of bioflavonoids and other substances normally associated with vitamin C in foods, as well as minerals that make it easier to absorb. This is just one example of the processes that go into making nutritional supplements derived from natural sources.”

Products include nutritional supplements such as Coral Calcium, Liva-Vite, Min-Col, Vascu-Min and Vega-Lax herbal supplement

“The Munson mixer is ideally suited to blending these minute quantities of additives,” says Mark Brown, Production Co-ordinator, who is a graduate chemist. “The blender’s rotating drum has internal mixing flights that provide a four-way mixing action — continuous tumbling, turning, cutting and folding — to ensure the thorough and rapid intermixing of all ingredients, even trace amounts, with zero stratification and segregation.”

Maximum Flexibility

Daily Manufacturing produces more than 50 blended products in batch sizes ranging from 15kg up to 200kg. “The mini mixer thoroughly blends a batch in less than half the time required by the ribbon blender, greatly increasing our productivity, and is flexible enough to meet our current and future needs,” says Brown. “With a capacity of 0.28 m3, it can easily handle a wide variation in batch sizes and provides equally efficient mixing at 100% down to 10% of maximum capacity, even with ingredients added in trace quantities.

“The bulk densities of our ingredients vary from 0.38–0.45g/cm3 and often have disparate particle sizes. Although none of our current products requires the addition of a liquid spray during mixing, the mixer has this capability should we ever need it.”

An important feature was 100% discharge upon completion of the mix cycle

With such a diversity of products, ease of cleaning between batches was an important consideration in selecting the mini rotary batch mixer. “On average, we change products being processed in the mixer several times a week,” Brown explains.

“An important feature was 100% discharge upon completion of the mix cycle, with only an insignificant amount of residual dust. It’s pretty easy to get rid of that small amount of residue by rinsing the blender with hot water containing surfactants, running it for about ten minutes and then doing a plain hot water rinse, especially as all the interior areas are readily accessible for fast, thorough sanitising. The entire process takes only about 15 minutes, compared with the 30 minutes it used to take to clean the ribbon blender.”

Built to Pharmaceutical Standards

The rotating drum has internal mixing flights that provide a four-way mixing action

The mixer’s internal mixing flights are spaced for easy access and continuously welded to the drum wall for total product discharge. All internal welds are polished and have a minimum 6.35mm radius to eliminate corners, cracks and crevices for material entrapment and are polished to better than 32 Ra (surface roughness average).

All product contact surfaces are constructed of stainless steel and its support structure and guards are epoxy painted. The Munson mixer now handles all of Daily Manufacturing’s production needs. The company has never had a problem complying with FDA sanitation standards and regularly passes inspections, according to Dr Daily.